Mining ESG Insights:

Achieve Zero Harm +

Zero Carbon.

Scroll down to access free resources and discover how Industry 4.0 technology can enable you to improve & track ESG performance, make reporting effortless + achieve zero harm and zero carbon objectives.

Industry 4.0 technology enables miners to get the real-time ESG metrics you need + all-new abilities to improve them from anywhere.

At all stages of the mining lifecycle and across the entire value chain the environment and community are affected and impacted in multiple, evolving ways.

Regulatory limits, industry standards and judicial intervention has shaped miners’ environmental approach over the last century, but adhering to these rules is expensive and we're reaching a point where compliance and old approaches are no longer sufficient - miners and the businesses that serve them need to do more with the goal now set at zero: zero harm, zero carbon, zero waste.

This isn't news. In numerous reports of global mining executives in recent years, Environment, Social and Governance (ESG) issues comes out as the major challenge facing the sector - above capital access, uncertain demand, workforce, productivity and digital/innovation. Why?

There are many answers to this. Outside of medium-to-long-term zero carbon arrangements (such as the Paris Agreement, COP26 and government targets), the societal and political zeitgeist has evolved to a point where, although the sector’s role in achieving energy transition is undeniable, it needs to do and be seen to do more. Simply put: poor ESG performance adds risk.

What's more, the consequences of missteps have grown significantly at both a corporate and individual executive level (see Rio Tinto’s experience at Juukan Gorge or Vale’s at Córrego do Feijão). Miners’ ability to expand or open new sites are now subject to stricter LTO and capital requirements that factor in short, medium and long-term ESG risks: the sustainability of the sector and success of the people that work within it are now even more directly tied to the environment and the community that surrounds their operations.

Industry 4.0 technology will play a significant and ever-growing role in enabling miners to seize new benefits; achieve their zero carbon, zero harm and zero waste goals by predicting and mitigating problems to prevent harm from occurring; and allow the mining sector to be the responsible environmental custodians (and prove it) that they need to become in the evermore environmentally-conscious future that awaits us.

Our sustaianability solutions enable you to effortlessly track these ESG + any other metrics in real-time:

- Air pollution per metric ton of output produced

- Carbon tonnage

- Closure status

- Diesel footprint

- Electricity purchased

- Embodied energy

- Energy usage

- Environmental incidents

- Fluoride emissions

- Fuel consumption

- Hazardous waste per ton of output produced

- Incidents with security providers

- Land footprint disturbed / regenerated

- Mineral waste stored / disposed

- Non-mineral waste stored / disposed

- NOx emissions

- Operating assets located in protected areas percentage

- PM2.5 & PM10 emissions

- Pollution incidents

- Project delays as a result of community opposition

- Proved/probable reserves in or near protected areas

- Radiation levels

- Recycled water percentage

- Recycled water withdrawals percentage

- Remediation score

- Renewable energy in energy mix

- SOx emissions

- Scope 1 emissions (tCo2e)

- Scope 2 emissions (tCo2e)

- Scope 3 emissions (tCo2e)

- Significant environmental incident rate

- Social Energy balance

- Spending on site restoration

- Sustainable Mining Indices

- Tailings and waste per metric ton

- TCFD status

- TOE footprint

- Total fresh water consumed

- Total fresh water withdrawn

- Total greenhouse gas emissions intensity

- Total lifecycle energy

- Total waste

- Utilization of mining waste percentage

- Water consumption rate

- Water discharge rate

- Waste recycled

- Wastewater volume

Industry 4.0 technology can enhance mining ESG metrics + achieve sustainable zero harm:

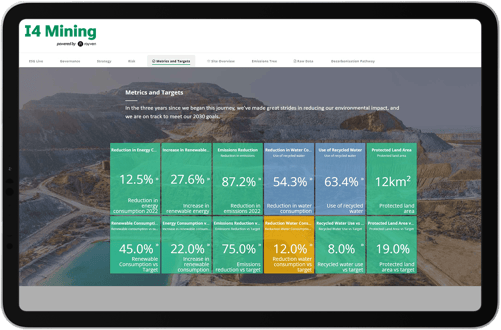

Accurately monitor real-time ESG performance + key TCFD, SDG, Carbon or any other metric, from mine-to-market across all-time.

Track waste & monitor pollutants in real-time. Predict + prevent harm using easy-to-use predictive analytics.

Model operational changes, aggregate risk profiles + see the effect of optimizations on zero harm ESG goals.

Alleviate the regulatory burden + get an accurate, single source of truth for all your environmental data with one-click reporting.

Unite business-wide environmental data, analyze it using Machine Learning, & enhance EIAs, SIAs + Closure plans.

Create a complete Industry 4.0 solution with automated, AI-led decision-making - transform your business.

Tell us the metrics you need and we'll tell you to get them, anywhere + anytime.

Free Insights: discover how Industry 4.0 technology can enable you to easily improve your ESG performance, both fast & affordably.

Report | Solving the ESG Conundrum: Industry 4.0 Technologies' Role in Enabling Miners to Achieve their Strategic Zero Harm, Zero Waste & Zero Carbon Objectives.

Discover how Industry 4.0 technology can enable the mining sector to achieve strategic ESG goals.

The challenge (and benefits) of an enhanced ESG focus in mining

SDG and ESG goals have now taken centre stage within the mining sector and it's just as well - the evidence suggests it could improve miners' performance.

Mining ESG Industry 4.0 AI + IoT use cases: Part 3 - Holistic operational analysis

In this final blog in the series, we look at the strategy and analytical advantages of using a Sustainability Performance Platform that's capable of both adaptive and predictive analysis of your complete operations - all in real-time.

Mining ESG Industry 4.0 AI + IoT use cases: Part 2 - Real-time monitoring

In this, the second blog in the series, we look at the ways that Industry 4.0 technology can provide miners with enhanced real-time insights that enable better decisions to be taken, faster - plus much more.

Why electrification won't be enough to achieve 'zero' goals

Electrification has an important role to play in achieving zero goals, but it needs quite a bit more...

Mining ESG Industry 4.0 AI + IoT use cases: Part1 - Enhancing operational performance

This is the first in a series of three blogs examining the different applications of Industry 4.0 technology in solving the mining sector's SDG and ESG goals.

Real-time data analysis failings are hurting miners' brand

A lack of real-time data analysis capabilities in the mining sector is failing workforces, communities, and the environment - here's how to fix it.

Data consolidation gives miners the foundation needed to succeed

Data consolidation and the ability to analyse it in real-time provides miners with the perfect cocktail for success both strategically and operationally.

Industry 4.0 (and zero goal) attainment: the technology blueprint

Industry 4.0 status is not achieved through a single solution.

Want to see how you can track ESG performance in real-time + utilize predictive analytics?

Book a demo today.

I4 Mining | Brochure

Create a complete Industry 4.0 solution with automated, AI-led decision-making - transform your business.