Sustainability goal attainment: the technology blueprint

Blog

Achieving 2050 goals and key sustainability objectives cannot be achieved through a single piece of technology.

The fourth industrial revolution - where businesses build upon their use of computing power and automation with the adoption of intelligent, autonomous systems that can leverage complex data sets and machine learning to deliver AI-driven enhancements in real-time - will be key to miners achieving their long-term sustainability objectives.

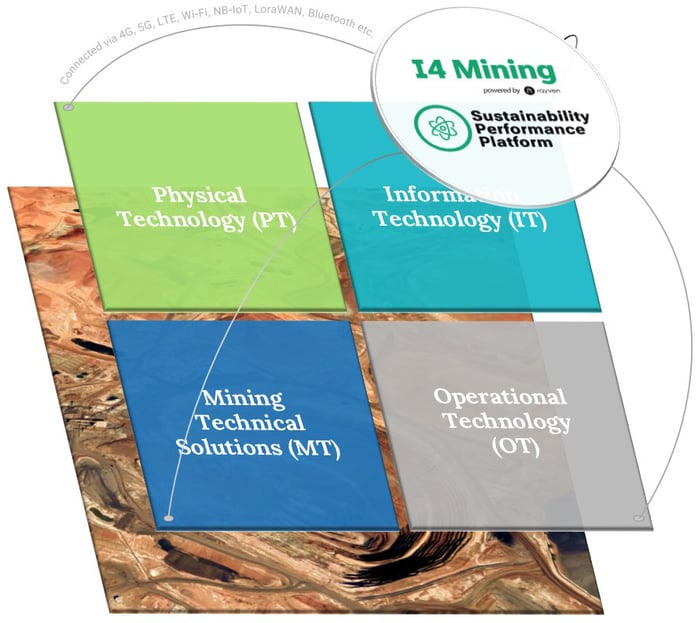

There is already a vast array of ‘Industry 4.0 solutions’ available. From new forms of IT and Mining Technical solutions (MT), to Physical Technology (PT) and Operational Technology (OT); all boast outcomes that deliver on efficiency, safety, productivity and other ESG-orientated goals.

What these individual solutions and technologies cannot do, however, is deliver holistic change or fuel the attainment of strategic zero harm, zero carbon and zero waste goals on their own. What they do is deliver the additional functionality (and data sets) that will be needed to succeed with sustainability.

For example, systems that allow a drill rig to be run remotely are great at improving safety, but aren't going to analyze its sustainability performance. So, in order to run mining operations optimally and to deliver on sustainability goals, it’s necessary to collate and analyze this sort of data (such as emissions) to create a ‘Big Data’ set which you can then select and monitor the key ESG and SDG metrics from your entire operations which are indicative of performance. It's about lag vs. lead measures.

To do this, miners need to adopt a new piece of technology that can sit above all of their other technology: a Sustainability Performance Platform.

A Sustainability Performance Platform sits above all your technology and operations. It integrates with all your other systems, platforms and data stores, and forms the basis of easy-to-use sustainability solutions through which you can improve how you monitor, manage, and optimise your ESG performance.

Sustainability Performance Platform

Our sustainability solutions are built on the Rayven Sustainability Performance Platform which can connect with all technologies (Cloud or on-premise), allowing for data from anywhere to be collected, united, and analysed. This enables miners to monitor your ESG and SDG performance accurately, report on industry frameworks and business objectives in a single click, and easily leverage predictive analytics to forecast and improve ESG performance from mine-to-market.

Physical

Technology (PT)

The internal asset/plant software and hardware (e.g. IoT sensors) used to connect physical assets, orient them allowing for real-time monitoring and control.

Information

Technology (IT)

Core central business systems, such as ERP, CRM, Business Support and Infrastructure Management. Usually managed by the CIO.

Mining Technical

Solutions (MT)

Solutions involved in individual element of business and mine operations, such as modelling, planning, health & safety and management platforms. Often managed by TSM.

Operational

Technology (OT)

Systems and technologies involved in the execution and control of mining environments, such as in the plant and beneficiation processes (e.g. SCADA).

Technology that's only designed for a single stage or to operate a specific asset can't improve overall functions, won’t deliver holistic transformation and will mean that you’ll always fall short of strategic sustainability goals.

A sustainability solution built on a Sustainability Performance Platform can provide you with assistance across your full operations. Capable of integrating your full technology stack plus old and new plant, it can provide the overarching strategic insights that senior management teams need as well as offer guided adapted intelligence to those in the field, drill-down into specifics, and make better ESG and SDG decisions based on real-time performance.

I4 Mining is a sustainability technology provider to the mining sector, offering ready-to-deploy ESG solutions that help miners to succeed both strategically and operationally without ever getting in the way of good business.

Our solutions enable you to easily develop strategies, deliver accurate sustainability metrics and reports in real-time, improve sustainability and business performance, as well as make predictive analytics and forecasts part of your everyday so that you can reduce risks and optimise from mine-to-market.

Speak to us today to book a demo and discover how you can get started on your digital sustainability journey.

Jared Oken

CEO @ Rayven

jared@rayven.io

LinkedIn

Want to know about industrial AI + IoT more broadly?

If you'd like to find out more about the technology that underpins all of our digital mining solutions, other industrial uses of AI + IoT, or are eager to get into the detail of precisely what AI and IoT technology are then visit the Rayven blog.