Mining Safety Insights:

Achieve Zero Harm

Scroll down to access free resources and discover how Industry 4.0 technology can enable you to improve mine safety + achieve zero harm.

Industry 4.0 technology enables miners to get the real-time safety metrics you need + all-new abilities to improve them from anywhere.

In the developed world, mining-related fatality and injury rates have trended downwards for decades due to significant safety improvements. However, in the past 20 years or so, numbers have plateaued - and this is no longer good enough.

Existing technology, process and regulatory changes have played a huge role in improving mining safety, but additional reductions and the sustainable attainment of 'zero harm' isn't going to be achieved without change.

Industry 4.0 technologies present the mining sector - arguably for the very first time - with the opportunity to actually reach zero harm.

From taking people out of harm's way, providing those in the field with real-time threat monitoring and predictive analytics, through to AI-led interventions that can remedy danger before it occurs; the mining sector now has at its disposal the tools to make being in the field as safe as being in the office.

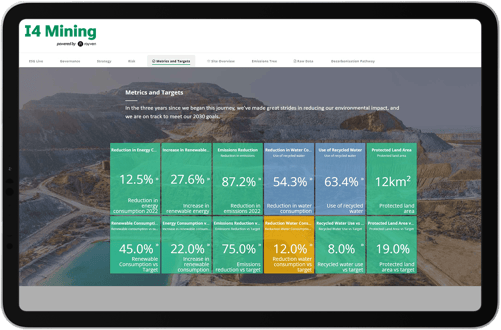

Our sustainability solutions enable you to effortlessly track these safety + any other metrics in real-time:

- Accident frequency rate

- All injury frequency rate

- CO Level

- CO2 TAW

- Corrective action completion

- COVID status

- DART Safety

- Employee perception surveys

- Employee Safety Score

- Equipment breakdown

- Fatality frequency rate

- Fines and prosecutions

- Frequency of refresher training

- Ground Vibration

- Heart rate

- Incident rate

- Inspections & audits completed

- Lost time incident frequency rate

- Lost Time Injury frequency rate (LTIFR)

- Lost time to injuries (LTI)

- Medical treatment injury rate (MTI)

- Near miss frequency rate (NMFR)

- Noise level (dB)

- NOx levels

- Occupational illness cases (new / existing)

- OHS status

- PM2.5 & PM10 levels

- Safety score

- Safety walk status

- Supplier safety performance

- Temperature

- Total case incident rate (TCIR)

- Total recordable incident rate (TRIR)

- Total recordable injury frequency rate (TRIFR)

- Training per employee

- Water level

- Worker compensation costs

- Workforce on voluntary training

Industry 4.0 technology can enhance mining safety + achieve sustainable zero harm:

Predict + prevent accidents, injuries & fatalities to achieve (& sustain) zero harm.

Get an accurate, complete view of evolving risks in real-time in a single pane.

Model process, equipment + personnel changes to see their impact.

Provide single-click regulatory compliance reporting + real-time analytics.

Get a real-time single source of truth for assets, functions, sites + business-wide.

Safely guide personnel + leverage automated, AI-led decision-making.

Tell us the metrics you need and we'll tell you to get them, anywhere + anytime.

Free insights: discover how Industry 4.0 technology can enable you to easily improve your safety metrics, both fast & affordably.

Report | How the Mining Sector can Achieve Zero Harm with Industry 4.0 Technology.

Discover how insights, interoperability, instruction and intelligence will enable miners to achieve their zero harm safety goals.

Mining Safety: The industry must recognise it has a fatality cycle

The mining sector needs to change its mindset and act if it's going to make any difference to current fatality rates.

Health & Safety Industry 4.0 applications in mining: Part 1

It’s not possible for a human to list every possible scenario and potential harm that may arise whilst mining - Industry 4.0 technology can.

Health & Safety Industry 4.0 applications in mining: Part 2

In this blog, we’re focusing on the operational areas where the application of a Sustainability Performance Platform can have significant impacts.

Why electrification won't be enough to achieve 'zero' goals

Electrification has an important role to play in achieving zero goals, but it needs quite a bit more...

The relationship between Industry 4.0 technology + zero harm

Industry 4.0 technologies present the mining sector - arguably for the very first time - with the opportunity to actually reach zero harm.

Real-time data analysis failings are hurting miners' brand

A lack of real-time data analysis capabilities in the mining sector is failing workforces, communities, and the environment - here's how to fix it.

Data consolidation gives miners the foundation needed to succeed

Data consolidation and the ability to analyse it in real-time provides miners with the perfect cocktail for success both strategically and operationally.

Industry 4.0 (and zero goal) attainment: the technology blueprint

Industry 4.0 status is not achieved through a single solution.

Want to see how you can track safety performance in real-time + utilize predictive analytics?

Book a demo today.

I4 Mining | Brochure

Discover more about I4 Mining, our solutions and the technology that they're built upon.